About Us

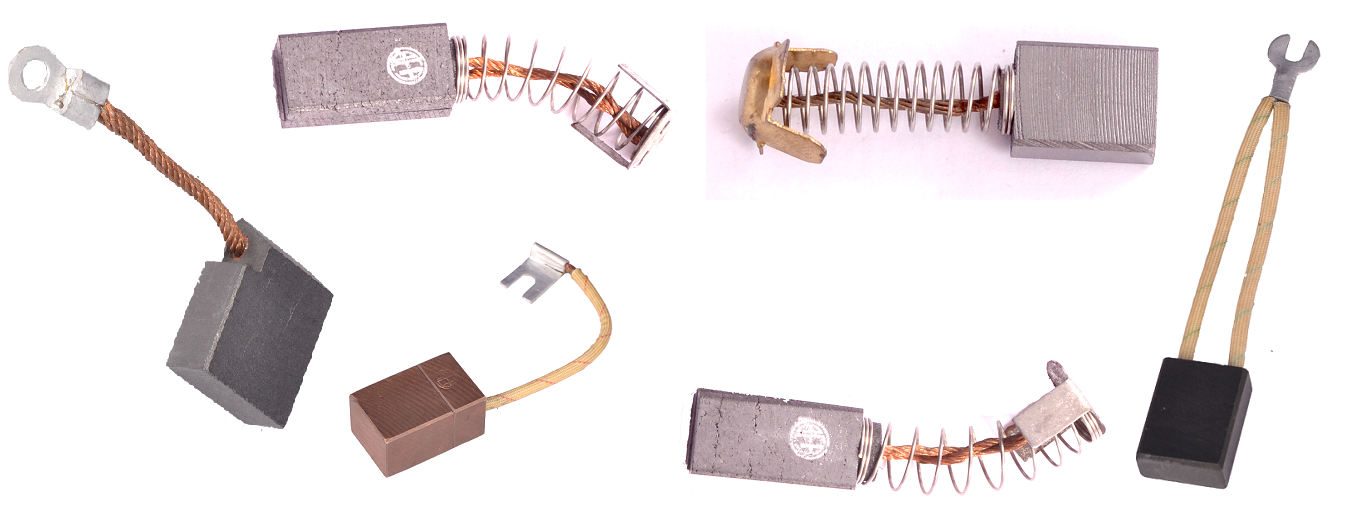

BEA Electronics is one of the leading manufacturers of high quality Texcarb Carbon brushes in India. A Carbon brush is the device which conducts current between stationary wires and moving parts, most commonly in a rotating shaft or commutator. Typical applications include industrial motors, traction motors, tachometers, slip rings, large and small household appliances, power tools, alternators, electric generators and automobile industry.

Carbon brushes in India. A Carbon brush is the device which conducts current between stationary wires and moving parts, most commonly in a rotating shaft or commutator. Typical applications include industrial motors, traction motors, tachometers, slip rings, large and small household appliances, power tools, alternators, electric generators and automobile industry.

One end of carbon brush consists of carbon/graphite composition which is unique and adequately conductive to perform electrically and has lubricating characteristics to maintain low friction for satisfactory mechanical performance. The other end of the carbon brush usually consists of a terminal or cap to make a stationary electrical connection.

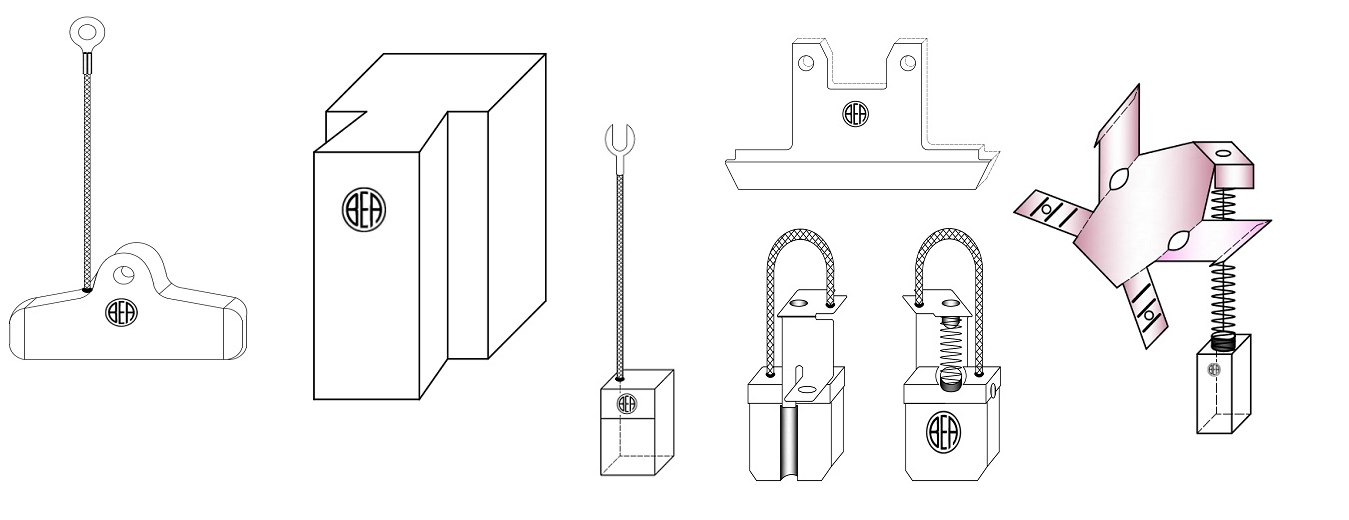

Texcarb carbon brushes are specially developed for textile machinery, automobile and power generation industry. BEA Electronics has redesigned brush holders to make trouble-free long life carbon brushes. Hence Texcarb

carbon brushes are specially developed for textile machinery, automobile and power generation industry. BEA Electronics has redesigned brush holders to make trouble-free long life carbon brushes. Hence Texcarb carbon brushes are very economical and cost effective solution.

carbon brushes are very economical and cost effective solution.

BEA Electronics also welcomes custom design requirements.

Classes of carbon materials

A) Electro graphite materials

This class of material is the most widely used and the various brush grades are identified with letters such as EG, SA and RE. With electrographite materials the carbon is converted into graphite by heat treatment at a temperature in the order of 2500 °C. Electrographite material has the characteristic high thermal and electrical conductivity of graphite and is additionally very resistant to burning. Consequently electrographite materials are capable of carrying heavy loads. As a result of the especially high processing temperatures, electrographite grades are generally of high purity, causing minimal collector wear.

B) Copper graphite materials

This class of material are identified with letters such as CM, RC, MK and CG. Metal powder and graphite are mixed, melded and then subjected to a heating process. The metal powder is used to produce metal or copper materials, whilst silver is employed to produce silver graphite materials.

A combination of good sliding ability of the graphite and the high conductivity of the metal is achieved, which suits machines with high electrical load on the brushes. Silver graphite materials are mainly used on tacho generators or for measuring purposes.

C) Resin bonded materials

This class of material are identified with letters such as IM, RX and BG. The grades are based on natural and /or electrographite materials, mixed with artificial resins. This type of bond produces a high electrical resistance which endows the grades with extremely good commutating abilities, combined with high contact drop and low friction.

Its current carrying capacity is limited. These materials suit to small dc machines and three phase ac commutator motors.

D) Natural graphite materials

This class of material are identified with letters such as HM, 634 and LFC. Natural graphite is mixed with pitch or resin, subject to a heating process. These materials are mainly used on turbo alternator sliprings within the power generation industry suitable for low load and high speed.